Time: A Tradies Most Valuable Resource

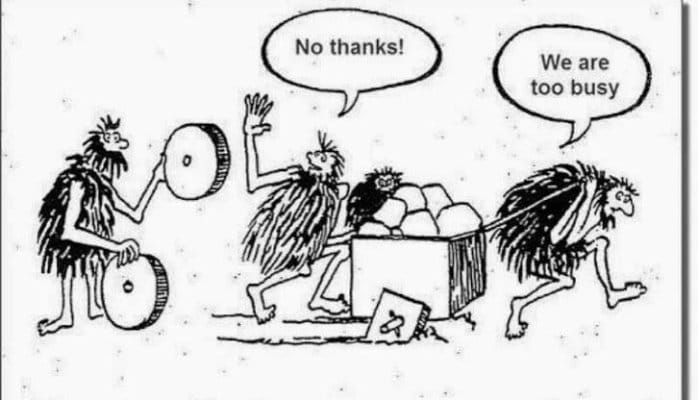

We came across this meme yesterday and it perfectly sums up our most valuable resource – TIME. You’ve heard the saying “Time is money,” right? That phrase certainly applies to the job site. Time lost by your employees at job sites translates into actual costs to your business. By taking back that time, you cut business costs and boost the bottom line.

The trick to taking back that time is identifying the biggest time wasters and taking steps to minimize or eliminate them.

1. Failure to Plan

Did you know, that only 65% of a contractors crew time, is spent on the actual job installation? So where does the rest of the time go? By some estimates, the other 35% is spent on tasks such as taking trips across the site, cleaning up, setting up, obtaining permits and looking over plans. There is a way to increase the time spent on installation instead on the other menial tasks – pre-planning. This helps to maximize your employees’ productivity for they know exactly what they are meant to be doing and when.

Innovation & Technology are big news right now – some guys are using every piece of technology available to them, whilst others are hoping they’ll get through the next 5 years to retirement without having to pick up a smart phone. “If you don’t keep up with technology, it will run away from you.” Using technology to pre-plan your job will help to cover all aspects of the installation – right down to the finer detail.

There is a way to increase the time spent on installation instead on the other menial tasks – pre-planning. Mapping out a job in detail, all before starting it helps to cut time spent on activities like studying the plans, laying out the work again to get it right the second time – which is very frustrating! Pre-planning helps you get the right tools for the job and saves you time later on having to search for them. A plan outlines how the job will get done and sets a schedule with deadlines. It can break down the schedule into smaller tasks such as familiarizing oneself with the permit requirements for the job and ensuring those permits are in order – this reduces tips and slowdowns when the job is under way. Analyzing costs is also included in this plan – this ensures that money is not being spent unnecessarily during the job installation.

The pre-plan also accounts for how potential weather setbacks and hazardous materials will be dealt with; and includes a labor schedule, a method to track labor and a way to show how materials will be brought to the site, and disposed of from that site. By building lead time into the project via planning, you can also shop around for, and compare prices on, materials and equipment.

Because the plan is intended to keep everyone involved with the project on track, make sure you’ve sent it to all the players early on, have communicated with them and have asked for their feedback (including whether they have changes to the plan). This will streamline processes and help the project to move along efficiently. It will build teamwork too if everyone is included and interested in the job installation.

2. Lack of the right equipment

Employees who are at the job site but not working could be waiting for instructions on what to do. Or, they may be awaiting materials delivery — including gasoline to power a generator — or access to locked areas. Whatever the reason, they’re on the clock but not working. There’s an easy way to figure lost costs here: the hourly wage minus the downtime.

To keep waiting to a minimum, your leadership skills need to come into play.

You’ll need to provide clear direction to crew members about what they should do when work slowdowns occur. Tell them they will need to keep themselves busy and on the job when waiting for deliveries and the like. This relates back to pre-planning – having a clear plan ensures everyone has a job to do and when.

Other things you can do:

- Clarifying the job roles of each employee is important. It helps them to understand what they need to complete that day and how. Encouraging them to ask queries about the job makes sure they know what is going on at all times.

- Make contact information available. Post a laminated list of important telephone numbers in a key location. An employee can call a delivery person with the order number, for example, if the delivery doesn’t arrive by a specified time.

- Stage your job site at the end of each day to be sure it’s ready for the next day’s work. This minimizes setup time.

- Track job performance. This keeps you on top of worker performance and encourages your employees to stay on task. You’ll also find areas where downtime can be minimized.

We have vans that go down to Auckland daily – simply call us on 0800425800 to meet you at your job site for the tools your require!

4. Accidents

To avoid accidents on your job site, mandatory safety meetings at the start of each day, help to make employees aware of the dangers and consequences of what could happen. It is important to give out safe-handing reminders regarding machinery, materials and tool setup and operation. Everyone on the site should be required to wear proper safety gear, including hard hats and eye protection. Those working on rooftops and scaffolding must be wearing harnesses. Exhaustion is another cause of accidents when workers aren’t paying the proper attention to the job. Making workers take regular breaks can minimize this happening.

5. Disorganization at job site

This is similar to the other four factors. Messy job sites can cause accidents and prevent workers from working efficiently.

All walking and working areas must be clear and clean – this includes keeping stairways and passageways free of materials, supplies, and obstructions. Spills should be cleaned up immediately, or else the area is cordoned off. Tools and materials that aren’t being used in the work area need to be removed and stored in a separate place. Any toilet facilities must be kept clean and sanitary.